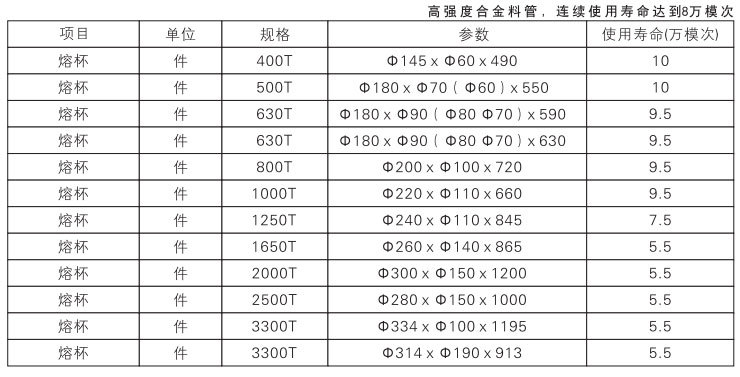

Crucible

Classification:

Details

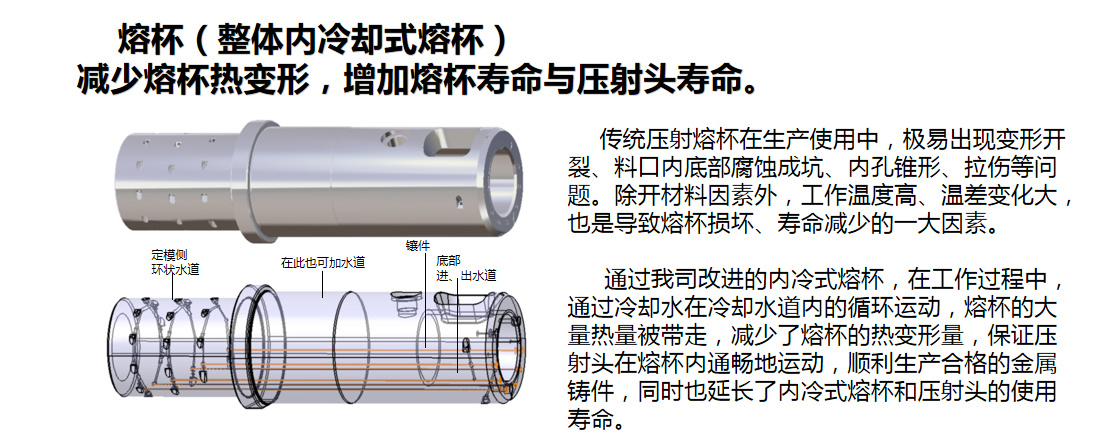

Traditional injection melting cups are prone to deformation, cracking, corrosion pits at the bottom of the material inlet, conical inner holes, and pulling issues during production and use. In addition to material factors, high working temperatures and significant temperature changes are also major contributors to the damage and reduced lifespan of melting cups.

Through our company's improved internal cooling melting cup, during the working process, the circulation of cooling water in the cooling water channel carries away a large amount of heat from the melting cup, reducing thermal deformation and ensuring smooth movement of the injection head within the melting cup, successfully producing qualified metal castings while also extending the lifespan of both the internal cooling melting cup and the injection head.

melting

during

injection

Other Products

I want to consult

Is there anything that makes you particularly satisfied or needs improvement while browsing our products? Your consultation or suggestions will directly help us improve the quality of our products and services, bringing you a more intimate experience.

*Please fill in the above fields (fields marked with an asterisk are required), and we will reply to your feedback as soon as possible.